What is warehouse management software and why does your logistics operation need it?

Table of contents

Quick Access

Modern logistics demands pinpoint accuracy at every step of the supply chain.

However, many companies still face daily challenges such as inventory errors, lack of visibility into the flow of goods, shipping delays, and poor space planning.

These problems not only affect operational efficiency but directly impact customer satisfaction and profit margins. This is where a key solution comes into play: warehouse management software.

What is warehouse management software?

Warehouse management software (WMS) is a digital tool designed to optimize, automate, and control all operations performed within a warehouse.

“These applications offer functions such as receiving, putaway, stock location, inventory management, cycle counting, job interleaving, wave planning, order allocation, order picking, replenishment, packing, shipping, labor management, yard management, and interfaces to automated material handling equipment,” detailed the firm's documentation Gartner.

This type of technology not only organizes information in real time, but also enables smarter decision-making, reducing errors and maximizing resource utilization. By integrating warehouse control system software, companies can achieve full traceability of each item and complete visibility over their inventory.

Common pain points in warehouse management

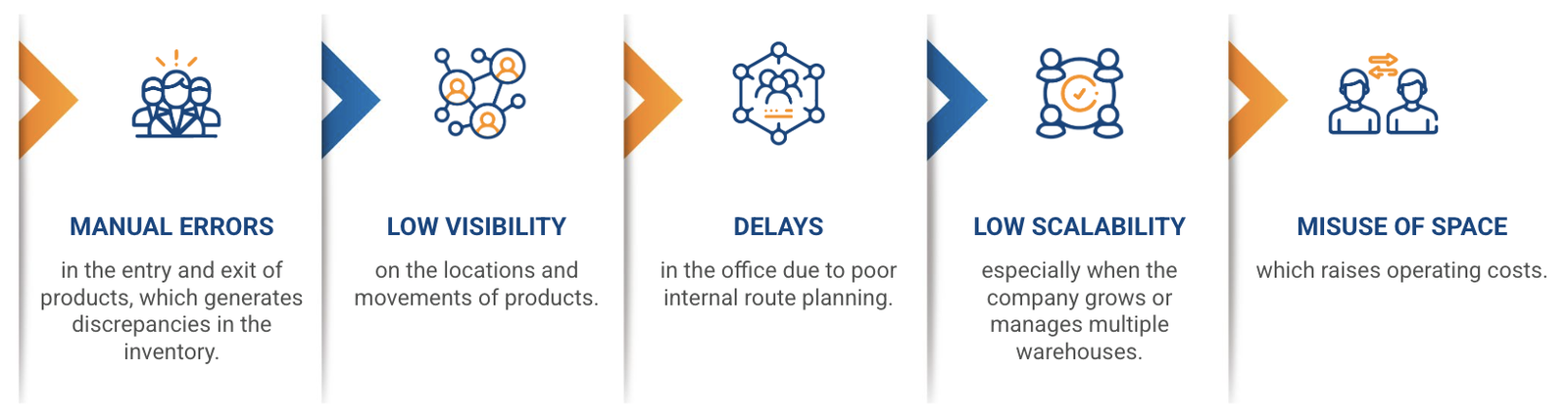

Before implementing warehouse scheduling software, many companies face a series of issues that hinder their logistics growth:

- Manual errors in product input and output, leading to inventory discrepancies.

- Lack of visibility into product locations and movements.

- Delays in dispatch times due to poor internal route planning.

- Difficulty scaling operations, especially as the company grows or manages multiple warehouses.

- Inefficient use of physical space, which increases operating costs.

These accumulated inefficiencies represent economic losses, downtime, and wear and tear on operating teams.

“Inventory management is one of the most significant financial challenges for warehousing operations. Storage costs, obsolescence risks, and inefficient storage can drain resources,” they noted in a Deloitte article on the topic.

Why does your logistics operation need this tool?

Incorporating warehouse management software is a strategic decision that transforms the way your logistics center operates. These are the main benefits this technology offers:

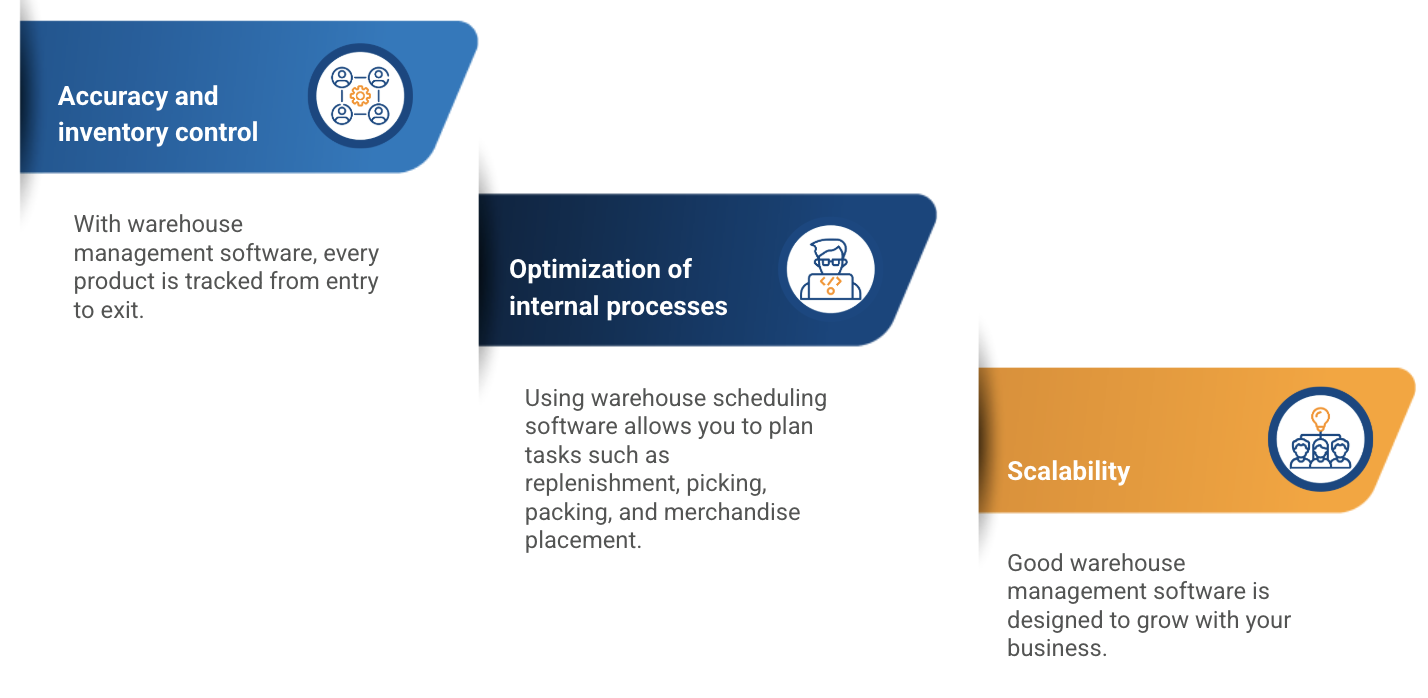

Inventory accuracy and control

With warehouse control system software, each product is tracked from entry to exit. This eliminates inventory errors, allows for more efficient audits, and ensures that stock is always up-to-date.

Optimization of internal processes

Using warehouse scheduling software allows for automated planning of tasks such as replenishment, picking, packing, and merchandise placement, reducingreducing lead times and increasing staff productivity.

“Through data-driven approaches such as predictive analytics and centralized inventory centers, organizations can optimize inventory levels, reduce waste, and maintain service excellence,” explained a Deloitte article in Deloitte.

Reducing operating costs

By minimizing errors, making better use of space, and reducing time at each stage of the process, companies can significantly reduce their operating costs.

Improved customer service

By meeting faster and more accurate delivery times, the end customer experience is improved. A correct order delivered on time builds loyalty and differentiates the company from its competitors.

Scalability

Good warehouse management software is designed to grow with your business. Whether you manage a single warehouse or multiple distribution centers, the solution can easily adapt to new logistics scenarios.

Key features of good warehouse management software

When choosing warehouse scheduling software, it's essential that it has certain features that enhance your operation:

- Real-time inventory management: Instant visualization of available stock and its exact location.

- Integration with ERP and logistics systems: To maintain constant synchronization with other areas of the company.

- Picking and packing automation: Improves order preparation with fewer errors and greater speed.

- Space and route management: Optimizes warehouse use and reduces unnecessary travel.

- Reports and analytics: Key metrics for data-driven decision-making.

A comprehensive solution like warehouse control system software not only meets immediate operational needs but also enables a strategic view of the logistics area.

How do you know if your company needs this type of software?

If your company is showing any of these signs, it's time to consider warehouse management software:

- Constant increase in order errors.

- Outdated or inaccurate inventory.

- Frequent complaints about late or incomplete deliveries.

- Need to handle a larger volume of products without increasing staff.

- Difficulty visualizing warehouse performance.

These signs indicate that the operation is reaching a limit that can only be overcome with specialized technology.

Use cases: sectors where it becomes indispensable

Although any company with warehousing operations can benefit, there are sectors where warehouse scheduling software is practically mandatory:

Retail and eCommerce: where the volume of orders and returns is high.

Manufacturing industry: for the handling of raw materials and finished products.

Distribution and wholesalers: who work with multiple delivery points and logistics centers.

Food and pharmaceutical sectors: where expiration control, traceability, and special storage conditions are required.

In all these contexts, warehouse control system software acts as the backbone of operations.

The future of logistics is smart

The rise of technologies such as artificial intelligence, the Internet of Things (IoT), and automation are revolutionizing warehouse management.

According to a survey of 65 senior logistics executives by McKinsey, 70% said they plan to invest at least $100 million in automation over the next five years, with a greater emphasis on speed, process stability, and reduced labor dependency.

“The number of automated warehouses in North America is projected to grow at a compound annual rate of 8.3% over the next few years. At that rate, only a quarter of warehouses will employ some level of automation by 2027,” they noted.

Today, the most advanced warehouse management software includes predictive features, optimization algorithms, and customized dashboards that enable real-time decisions based on reliable data.

Adopting warehouse scheduling software is no longer a competitive advantage; it's an operational necessity. Companies that don't take this step could fall behind more agile and digitalized competitors.

Rootstack's experience in the logistics industry

At Rootstack, we have extensive experience implementing warehouse management software for companies in the logistics sector.

Our team has supported multiple companies in their digital transformation journeys, improving their processes, reducing costs, and optimizing their warehousing operations.